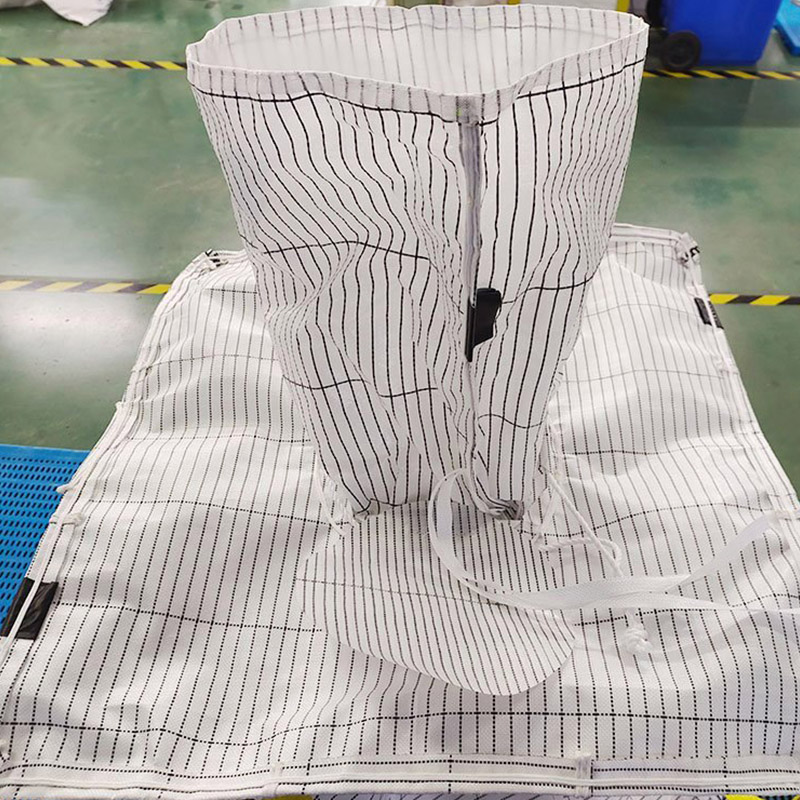

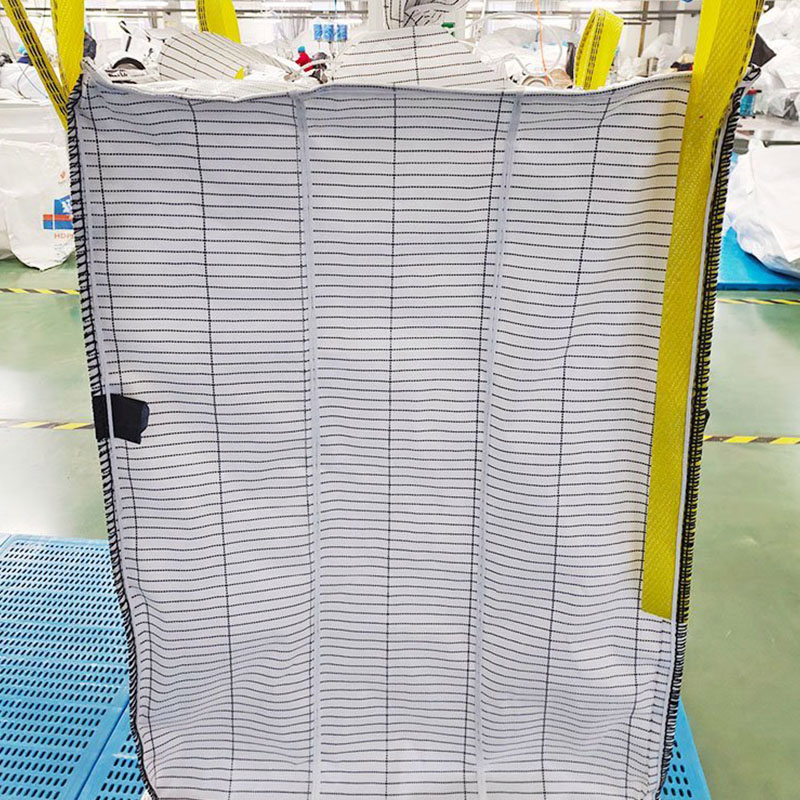

FIBCs are usually made of non-conductive fabric with interwoven conductive strands, which are less than 20 mm apart from each other.

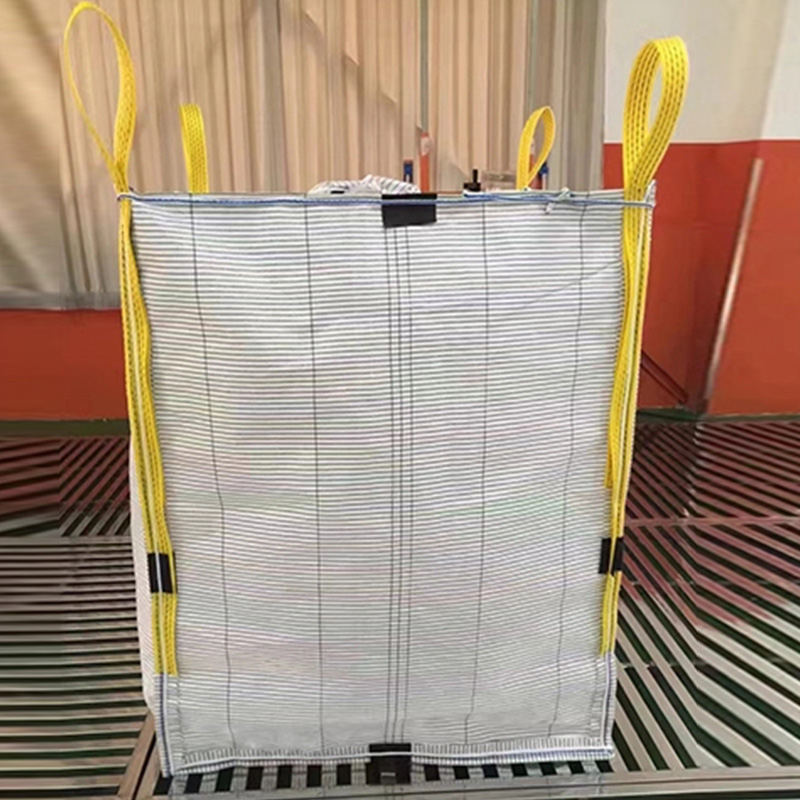

Model: 90x90x120cm

Conductive bags are typically made from non-conductive fabric integrated with conductive carbon threads spaced less than 20 mm apart.

The resistance of the connection points for the grounding leads must be below 10⁸ Ω, and grounding is essential during both filling and discharging processes.

Some conductive bags feature interconnected conductive loops to enable grounding through a (grounded) suspension system. When properly grounded, there is no risk of electrostatic discharge.

The inner or outer surface of conductive bags may include a thin coating. In such cases, the voltage on the conductive threads must not exceed 6 kV to prevent propagating discharges.

Therefore, Type C conductive bags are suitable for use in environments with combustible dust and/or explosive gases. As long as they are correctly grounded, these FIBCs can be used safely in hazardous areas.

Powders and granular materials can generate static electricity, which may in turn ignite flammable gases or cause explosions.

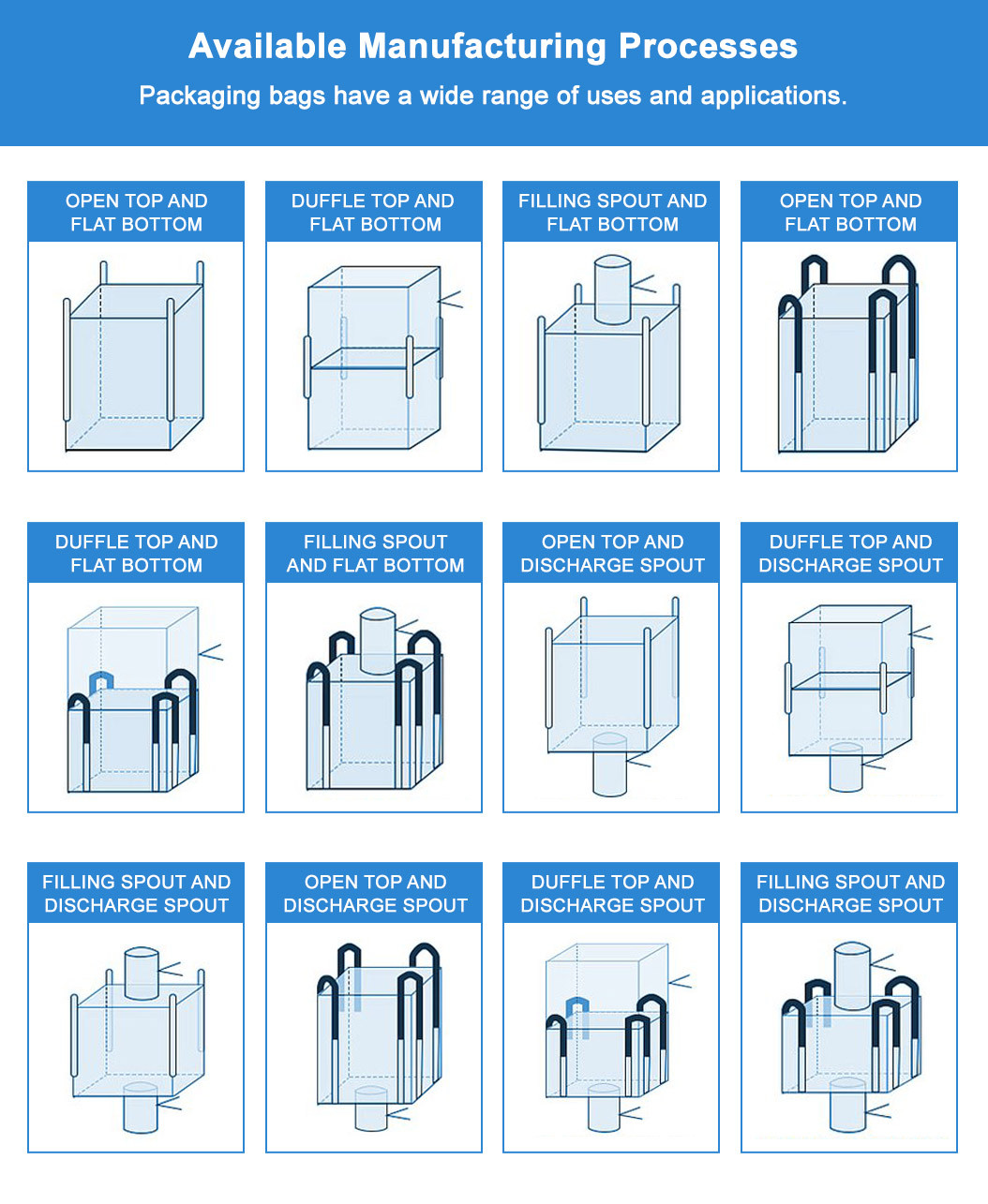

Related Products

Online Message

Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Request A Quote?